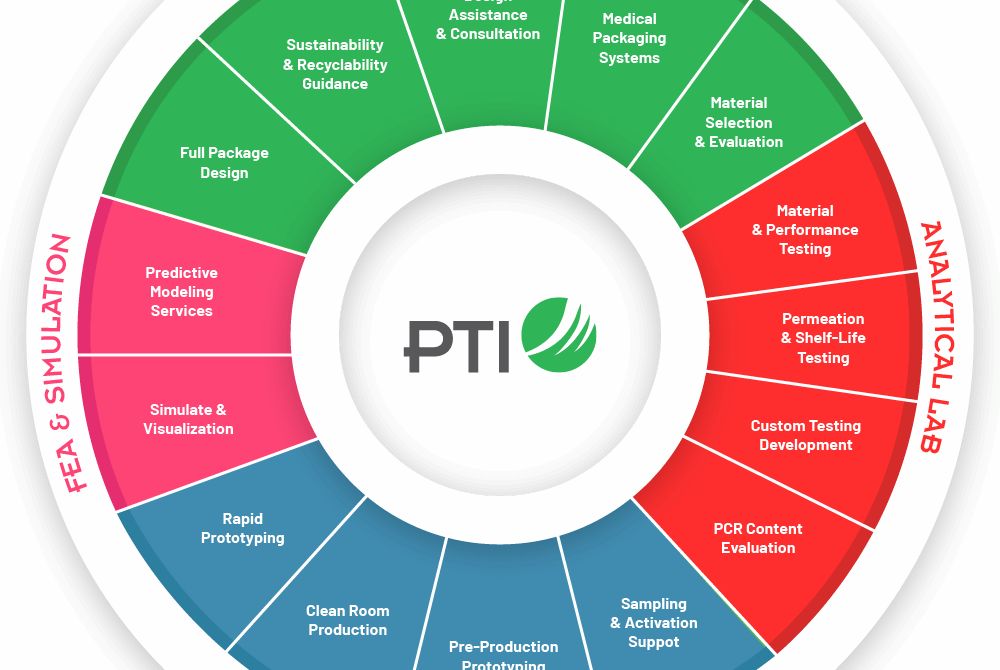

Over the past 40 years, PTI has partnered with the world’s top brands to bring packaging ideas to life, offering the speed, precision and technical depth to transform big visions into market-ready solutions. Whether you’re developing a next-generation bottle, refining a medical device container or validating a sustainable material, PTI meets you wherever you are in the process and helps you move forward with confidence.

Here’s how we do it:

Production Lab: From Prototype to Pre-Production

Our Holland, Ohio, facility is more than a lab. It’s a launchpad. From clean room medical packaging to rapid prototyping, we turn concepts into physical samples faster than most teams can book a kickoff meeting.

- Rapid and Functional Prototyping: 3D-printed concepts and blow-molded bottles in as little as 24 hours

- Clean Room Production: On-site sterile packaging systems, such as our award-winning CapSure trademarked system

- Pre-Production Sampling: Resin plaques, preforms and container samples to assess material behavior

- Scale-Up Support: Helping bridge the gap between design and market activation

Product Design and Development: Innovation That Performs

Great design isn’t just about aesthetics. It’s about functionality, manufacturability and market readiness. Our design engineers help move you from napkin sketch to shelf-stable product.

- Full Package Design: End-to-end development of bottles, preforms and more

- Design Optimization: Troubleshooting with agencies or internal teams to ensure concept viability

- Medical Packaging Expertise: Specialized systems for orthopedic and implantable devices

- Material Strategy: Custom polymer selection and additive evaluation for specific applications

- Sustainable Design: Recyclability assessments and eco-conscious material planning

Analytical Lab: Testing You Can Trust

When failure isn’t an option, data is everything. Our Pepsi-certified labs in the United States and Switzerland set the gold standard for performance testing, from polymer analysis to shelf-life evaluation.

- Comprehensive Testing: From melt index to secure seal, if it can be measured, we measure it

- Permeation and Shelf-Life Studies: Oxygen, carbon dioxide and moisture transmission for rigid and flexible formats

- Custom Method Development: Have a unique challenge? We build the test around your need

- PCR Evaluation: Gain a full picture of recycled content performance, from plaque to package

FEA and Simulation: Predict Before You Produce

Our predictive modeling team helps reduce risk, speed up development and optimize performance through virtual testing.

- Full FEA Reports: Simulate squeezability, blow molding outcomes, structural behavior and more

- Cost Efficiency: Minimize trial and error with digital insight

- Faster Approvals: Use simulation to build stakeholder confidence and reduce time to market

Ready to See What’s Possible?

Whether you’re a packaging engineer, sustainability lead or brand innovator, PTI is your partner from concept to commercialization. Let’s design smarter, test faster and build packaging that performs beautifully.