PTI Services

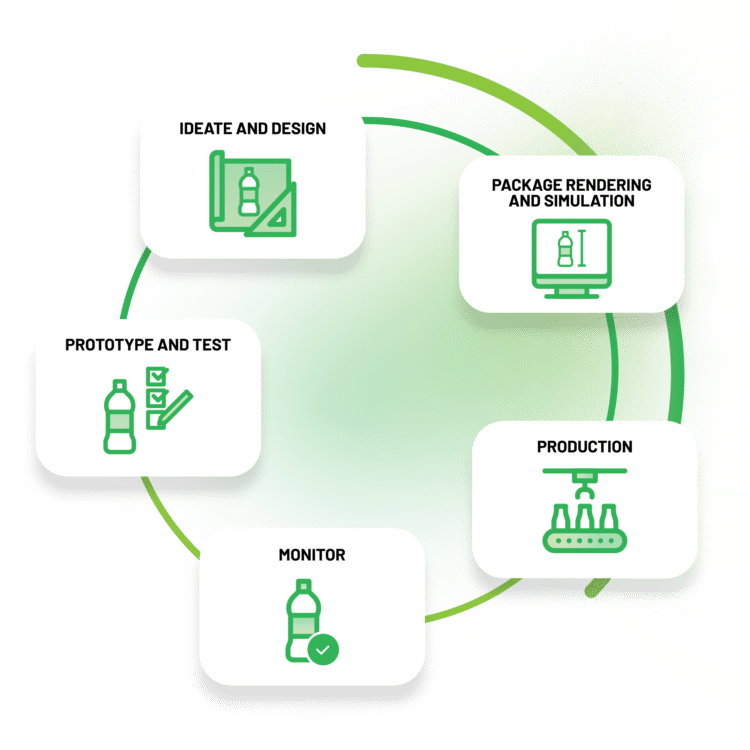

The PTI Approach

Ideate and Design

We perform in-depth consumer research and competitive analysis to form the foundation for our thinking. Then, our team of brand-oriented designers, material scientists and packaging engineers get to work, using state-of-the-art technologies and expert knowledge to concept and validate innovative packaging ideas that are tailored to exceed our customer’s goals and objectives.

Package Rendering and Simulation

This is where we bring your concepts to life digitally; providing a 3D product concept that is evaluated for various critical performance characteristics. Our rendering and performance simulation provides an accurate look into the performance of plastic containers and closures before investing in costly tooling and samples. By identifying and correcting any performance issues at this stage we are able to save time, costs, and future iterations – accelerating your product’s speed-to-market.

Prototype and Test

Our prototyping phase was designed to help customers visualize their concept or packaging design before going to production, affording them significant time and cost savings. During this stage, we continue to test and refine a design until the best possible configuration is determined and all performance objectives are met or exceeded.

Production

Our production capabilities are extensive, with the ability to produce anywhere between one and multi-million units, including sales samples, limited release production, and commemorative structures. Because our product production process is highly monitored and methodical, we are able to quickly and efficiently adjust our operations, significantly lowering the probability of error and its associated costs.

Monitor

PTI’s partnership doesn’t end with production. We make sure our customers are supported in production and logistical activities going to market, including plant support, machine startups and transportation logistics monitoring specifically tailored to a product’s unique shipping and delivery requirements.